Powder Coated Effects

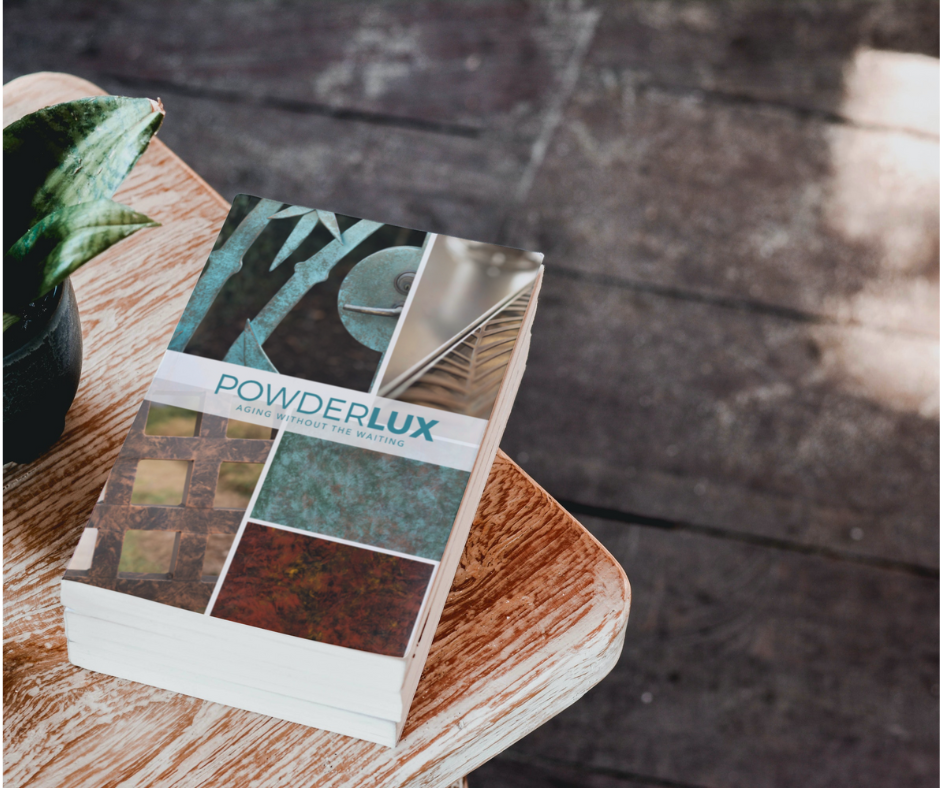

Patina Powder Coat & PowderLUX©

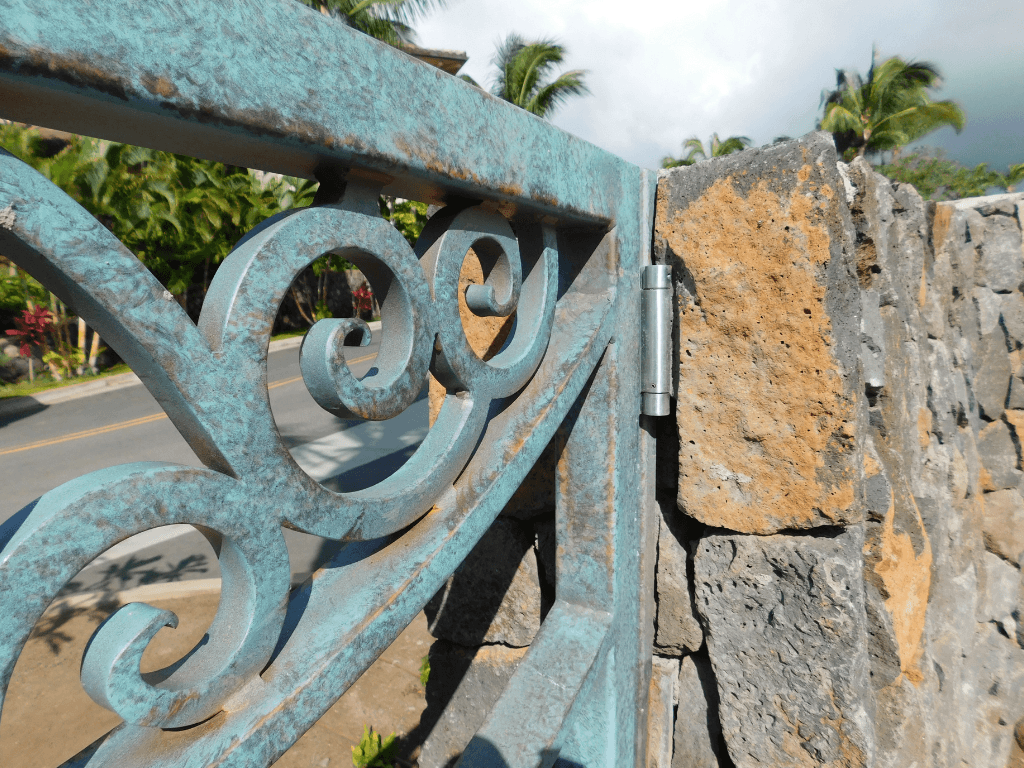

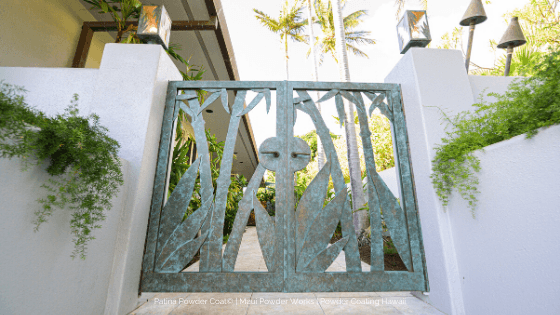

Bring patina powder coating into your next residential & architectural project without using expensive copper, liquid paint, sublimation, or chemical induction.

Whether you’re a product engineer, design house or luxury homeowner our VOC-free, powder coating effects provokes conventional thinking about patina coating metal. Our innovative technique & signature colors mimic traditional liquid & chemical looks without all the headaches of achieving them.

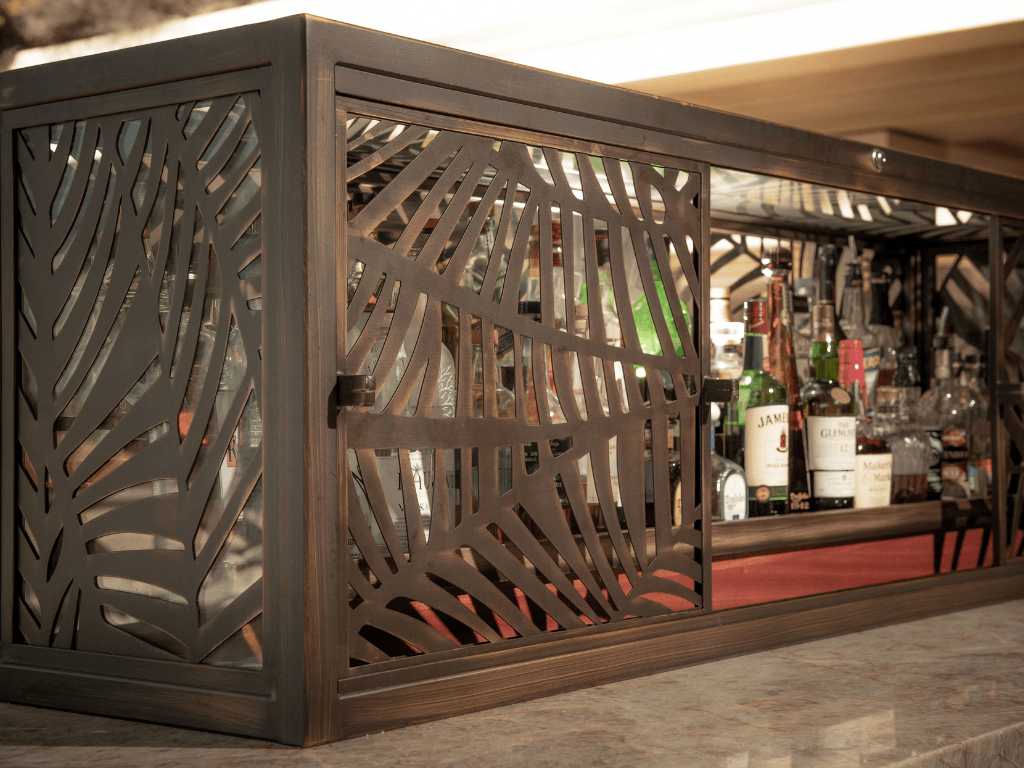

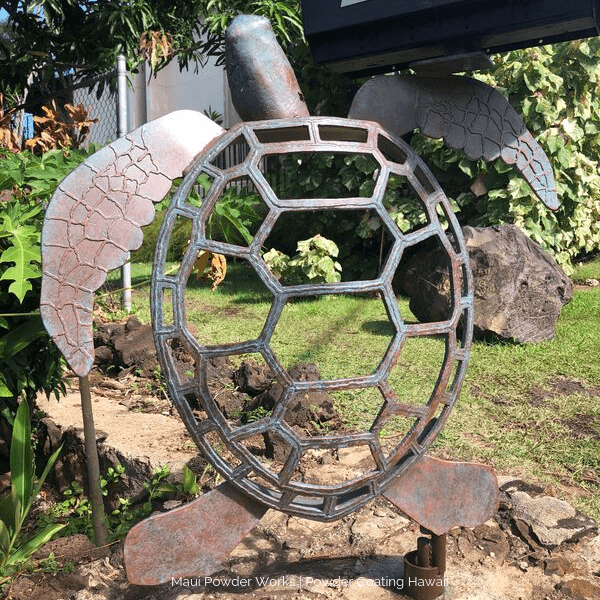

The PowderLUX© line delivers outdoor super durability with distressed finishes from aged copper, rust, blackened steel, brushed bronze & wood.

They’re so realistic even Mother Nature can’t tell the difference. . .

* individual samples available upon request

Our distressed powder effects mimic traditional liquid & chemical looks without all the headaches to achieving them.

What the industry is saying

Unlike today’s current applications that lend themselves to surface inefficiency, irregularity, and decay, effects using powder coating can give architecture, automotive, and home goods more controlled evenness and realistic natural looks consumers are demanding.

Here’s what some of our industry survey takers have to say about artistic patina powder-coated finishes:

Simulates the positive effects of weather and time, while in reality, being brand new and ready for years of use.

Looks aged but is very durable.

I have a current client that is looking for a finish just like this.

The appearance and the durability of a powder coat finish.

Great patina effect without waiting years.

Unique, one of a kind, eye-catching!

To convert new metal to look aged. Rock Solid!

It’s something exciting and new it would go over like crazy in my area.

I like that it is all powder coat…all the benefits of powder, but no chemicals or yuk from the patinas.

The rarity of it!

Aging Without the Waiting.

Markets around the world seek ready-made finishes that deliver aged copper patina finishes without the wait. Our method is a disruptive technology that impacts traditional ways to patinated finishes.

The innovative applications can produce beautiful, realistic finishes that are in demand without losing their toughness and durability the powder coating industry is known for like UV, chemical, and scratch resistance.

All Powder. No Paint.

It’s so realistic even Mother Nature can’t tell the difference. Our company has created visually stunning products to expand the metal coatings market. Our partner applicators can transform their clients’ everyday products into artistic mastery.

The first of these new finishes are called Patina Powder Coat. Tell us what you think.

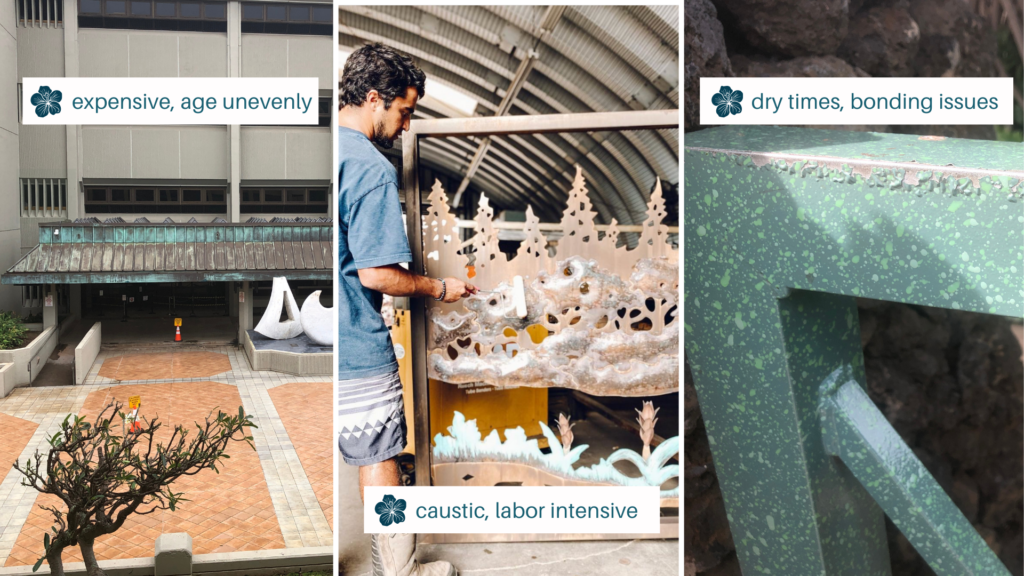

Traditional methods are problematic & expensive.

Current methods in the market today are acids and chemical mixtures. They create one of two outcomes, living finishes or faux painted finishes. Most are caustic and include solvents that are harmful to the environment and the applicator.

Here are some other limitations:

- Aqueous solutions, such as anodizing, are fallible if done improperly and reflect older production methods.

- These traditional methods can be slow due to dry times between coats.

- Clean-up is messy and may require extra floor space or ventilation during the curing process.

- Countries are limiting large-scale production.

Examples of aged copper, aging copper & failed paint methods

Today’s applications are toxic, messy & expensive

Due to restrictions and laws forbidding the use of such products, it puts downward pressure on the future of artistic finish methods, while demand continues to grow.

Additionally, dye-sublimation is an expensive alternative but its uses are limited when it comes to small part production & custom fabrications.

Tired of waiting for the paint to dry? Me too.

As a +20 yr. veteran of painting & restoration, I was inspired to create a new twist on achieving a realistic patina copper effect to metal in a non-traditional way.

Why?

Today’s liquid painted, naturally occurring or induced living finishes lend themselves to surface decay & inefficiency.

Our powder effects create a consistently layered finish needed to accomplish any size job. These powder coated performance finishes are better and faster to produce than traditional liquid faux applications.

That’s something faux painters just can’t do!

Learn how it all started. . .

Collaborating with one of Hawaii’s top fabricators inspired Ross Scott, owner of Maui Powder Works, to create this innovated powder effect to ignite a new genre of architectural faux finishes.

By using Powder Effects our company has been able to answer the most frustrating thing clients ask in powder coating today..What does powder coat look like brushed? Can I get a copper patina? Can I get it to look like blackened steel? Now we have that answer!

Denny Young -DJ Powder Coating, North Carolina

Become an Applicator.

We’re looking for more coaters. Imagine being able to inspire clients or open up new markets without buying new equipment. Our courses & products can transform everyday powder coating skills into artistic mastery. Deliver realistic distressed looks that customers want & traditional finishers can only dream about. Become a certified coater today.

Introducing PowderLUX©.

Expanding into new markets with new finish effects called PowderLUX©. Our Classic & Rustic Bronze effect is just one of the latest finishes we’ve created. It could exceed architectural expectations compared to expensive metals that require natural aging or chemical processes in manufacturing today.

Check out our entire line.